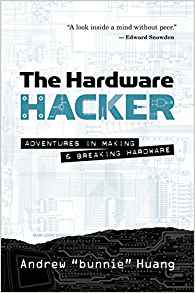

They are simply dust, fingerprint and scratch magnet, everything is summarised in the amazing book The Hardware Hacker: Adventures in Making and Breaking Hardware from Andrew ‘bunnie’ Huang

“My world is full of small frustrations like this. For example, most customers perceive plastics with a mirror finish to be of a higher quality than those with a satin finish. There is no functional difference between the two plastics’ structural performance, but making something with a mirror finish takes a lot more effort. The injection-molding tools must be pains-takingly and meticulously polished, and at every step in the factory, workers must wear white gloves. Mountains of plastic are scrapped for hairline defects, and extra films of plastic are placed over mirror surfaces to protect them during shipping. For all that effort, for all that waste, what’s the first thing users do? They put their dirty fingerprints all over the mirror finish. Within a minute of a product coming out of the box, all that effort is undone. Or worse yet, the user leaves the protective film on, resulting in a net worse cosmetic effect than a satin finish. Contrast this to satin-finished plastic. Satin finishes don’t require protective films, are easier for workers and users to handle, last longer, and have much better yields. In the user’s hands, they hide small scratches, fingerprints, and bits of dust. Arguably, the satin finish offers a better long-term customer experience than the mirror finish. But that mirror finish sure does look pretty in photographs and showroom displays!”