I’ve stumble upon a fairly common appliance, present in most home, built by million of unit, a TV.

This model is a GRUNDIG 40VLE5324BG with LED backlight: not starting anymore (one could see the “Grunding” logo or “signal not present” when flashing a strong light on it).

After seeking the net for a solution, removing dozen of screws, accessing the 100cm long LCD panel made of ultra thin glass with COG and flex PCB on side, I finally had access to the culprit: No, it was not the capacitor, not the LED driver, not even a LED but a single connector: PCB to PCB connector, designed to decrease assembly time and cost. As these LED string are serial driven (140V @ 400mA), a single failure will render the whole system useless.

Just wiggling the connector would start/stop the backlight:

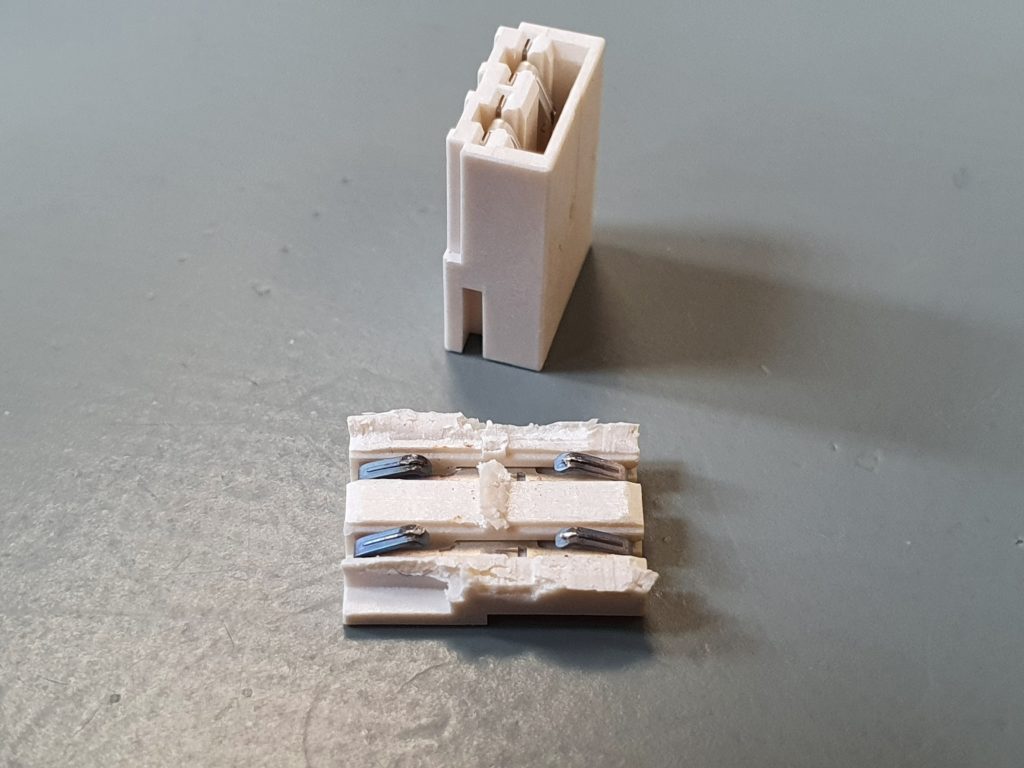

In this case, slight flex, oxidation or poor connector plating cause the problem, and as the LED as serial connected, the connector is oxidized from long arcing:

And the connector:

Let’s strap these connector with a piece of wire and fix this stuff!

Cheap 5ct clip will render a 500€/USD TV after few years! Hurray to planned obsolescence and global grow and economy!

Hey Tweepy, I have a thought I’d like you to consider in regards to one of your previous projects, the usb motion sensor that activates your monitor.

http://www.dotmana.com/weblog/2014/06/usb-motion-sensor-pir-to-wake-up-screen/?fbclid=IwAR0q9rBywevFaYfB_87o_XnZkEi6hoiHED4fE7V9hnHhY9FTo8Ru9rGWXg4

I have a similar project in mind, but it requires a weight sensor. Basically, here’s my situation. I’m an animator and I’m developing an animated TTRPG campaign for YouTube. Think Dungeons and Dragons, Critical Role and such, but with animation spliced in. Something I want for the show is for us to make physical dice rolls in an online game and for them to be displayed on screen without me constantly having to edit it in. To this end I want to build dice trays with webcams pointing down at them and weight sensors inside that when triggered switches the currently visible cam to the dice cam. The switching part isn’t hard. Basically you just connect two webcams to OBS then layer them on top of each other and set a hotkey to make the top one appear and disappear. However, if a dice tray with a weight sensor was controlling that hotkey…well you get the idea.

In practice, it’d look like this.

You roll your dice into dice tray —> hotkey is triggered which switches to the dice cam in OBS —-> Dice are picked up from tray —-> Weight returns to default range, a different hotkey is triggered again switching the dice cam off.

Put simply, imagine you’re playing Dungeons and Dragons online and everyone is on webcam, but every time someone rolls their dice, their camera switches to a cam placed over their dice tray, displaying the results of their roll. Based on what I saw in your previous project, it looks like it’d actually be pretty cheap to make something like this, but this isn’t my background so I’m not sure how to go about it. Maybe it’s requesting too much to ask you how I can build something like this, but I figured I should try.

I suppose the code would need to check for sustained weight for like half a second or something so you don’t trigger it by bumping into your desk or something like that, but I really think this idea could work without much complication.

Actually, now that I think about it, a sensitive button that’s triggered when the center panel of the dice tray lowers would be way more effective. You wouldn’t have to worry about calibrating a weight sensor or anything. As long as one die was enough to make that panel drop and hit the button, you’d be good to go.

The only thing you need to avoid misfires is something the code that says (only trigger the hotkey if the button has been pressed for at least such and such seconds) and vice versa for unpressed. Basically, the dice tray itself is just a button with a webcam strapped to it. The arduino and code do the rest.

Smthg like this?

https://hackaday.com/2019/06/20/automated-dice-tester-uses-machine-vision-to-ensure-a-fair-game/

Pingback: Low-Tech Fix Saves Expensive, High-Tech TV From Junk Pile

Pingback: Low-Tech Fix Saves Expensive, High-Tech TV From Junk Pile | Hackaday

Had the same issue with a Phillips TV, seem to be the same connectors. I only found the issue after replacing the backlight driver without any result.

Very interesting, do you have exact reference of the TV? Also any picture to share?

Unfortunately I didn’t make any pictures. I first opened up the TV about a year ago and fixed one connector. But two weeks back the problem came back so I soldered extra wires parallel to all the connectors I could reach to bypass connectors that might fail on me later. So probably it won’t come back but if it does I’ll make some photos.

It is the Phillips model 40PFL3208H/12

No problem for the pictures.

Thanks a lot for the reference, I’m sure it may be useful for visitors with the same telly and issue!

Pingback: LED light flicker: DIY measure it | DotMana