- ryanj » Mounting an EXT4 Clonezilla file in (Arch) Linux

monter une archive clonezilla pour accéder aux fichiers

(Permalink)

Mes trouvailles du jour : 30 August 2015

- Convert rgb pdf file to cmyk | Jaspreet Kaur Sarao

conversion d’un PDF RGB en CMYK

(Permalink)

Mes trouvailles du jour : 28 August 2015

- Pydio, formerly AjaXplorer

solution de partage de fichiers, multi utilisateurs, responsive, avec clients de synchronisation (dans version payante).

Une solution community open source est dispo.

(Permalink) - Mattermost

Un réseau social pour bosser en collaboratif (partage de fichiers, message privés ou public, recherche, responsive, etc.)

Le tout en auto-hébergeable (docker inside).

A tester !

(Permalink)

Mes trouvailles du jour : 16 August 2015

- Just Code!!: Mysql not starting.. corrupt innodb database

en cas de crash mysql au démarrage

Pour l’étape 3. Add the following line into /etc/mysql/my.cnf

innodb_force_recovery = 4

-> il faut que ça soit impérativement dans le chapitre [mysqld]

(Permalink)

Process audio file with Sox using Room EQ Wizard filter file

Rationale: compensate a speaker response curve (gain and phase) on a audio file.

Just came accross REW (Room EQ Wizard) (Linux, Windows, Mac), it let you plot the output of your speakers, then create a filter to compensate the flaws.

Once you created your finely tuned speakers, Export-> Filter as text file.

Then, it’s time to process the audio file with this filter, using the amazing Sox:

sox -q input_file.wav output_file.wav `awk ‘$4==”PK” { gsub(/,/,””,$6 );val=$6;printf ” equalizer “val” “$12″q “$9}’ val=”%’6.3f” REW_filter.txt`

That’s it: you have a outputfile with the correct compensation for your just analysed speaker.

Of course this method is for non-real time need.

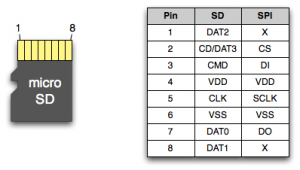

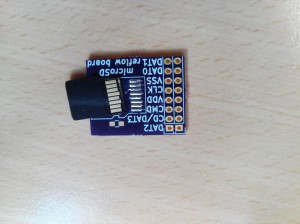

microSD card reflow: quick and dirty PCB with Kicad

Ever wanted to add a lot a flash memory to a small microcontroller? NOR flash or EEPROM are ok, but only for small size. For Gbit range, you need NAND, and with NAND comes CCR, LUT, wearleveling, etc… Furthermore, they are darn expensive in small volume.

SD and microSD card are very interesting: they cost nothing, and you just need a SPI interface as the controller is included.

Last night, I thought: “why not reflow a complete microSD card”, and save the cost of the socket, and PCB footprint size. As the card is composed of the same resin as chip casing and pins are flat bellow the microSD card and even gold plated, fore sure it should not be a problem to bring this to 270°C for 2-3 min….

Let’s try!

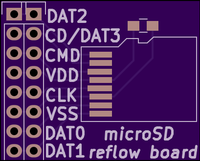

Then let’s create a small board, to try the reflow of a micro SD card and give access with some 2.54mm header.

Then let’s create a small board, to try the reflow of a micro SD card and give access with some 2.54mm header.

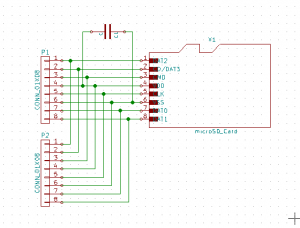

Lets open Kicad and start with the schematic with Eeschema:

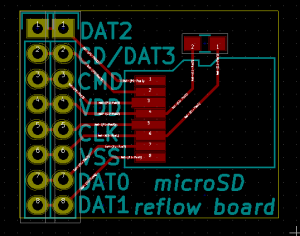

Then PCB new for the board layout:

MicroSD footprint and module for Kicad: microSD_Card

Let’s submit the gerber files to, you can order the board here (shared project): OSH Park

Total including USPS post mail: 4.10€

Total including USPS post mail: 4.10€

That was my fastest board made ever, 1h30 from searching the pinout to the confirmation email!

See you back in few week for the oven reflow test!

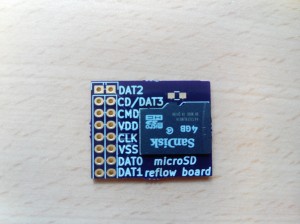

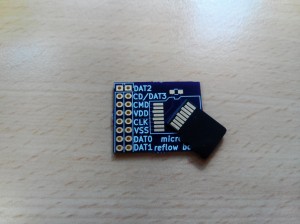

Update: the board and the reflow!

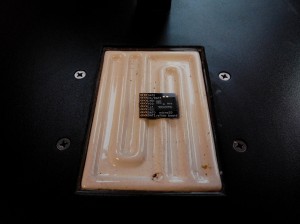

First, let’s clean it and apply some flux:

First, let’s clean it and apply some flux:

Then some solder on the pads, and flux again:

Then some solder on the pads, and flux again:

Time to turn the heating plate and IR reflow on:

Time to turn the heating plate and IR reflow on:

Just stir it a bit while it’s hot:

Just stir it a bit while it’s hot:

Houston, we have a reflow!

Then time to test: lets scavenge a super cheap reader microSD card reader:

And plug it: IT WORKS! After 3 min under the IR station, it does work.

I think I’ve to increase the pad size, in order to maximize the solder paste.

Now I’m confident sending to production, as I’ve quite a lot of theses cards in trays, ready for pick and place:

Mes trouvailles du jour : 5 August 2015

Mes trouvailles du jour : 29 July 2015

- Mailjet – Pricing

le compte gratuit semble déjà très complet

(Permalink)

Mes trouvailles du jour : 22 July 2015

Mes trouvailles du jour : 21 July 2015

- ObjGen – Live JSON Generator

Générateur de JSON à partir d’un model très simple à écrire.

Puis pour générer un schema JSON, utiliser :

http://jsonschema.net/index.html#/Et pour valider un schema :

http://json-schema-validator.herokuapp.com/

(Permalink)